Not completely satisfied with my hand-sculpted solera, I began devising a way to carve a perfectly radiused workboard dish using an inexpensive router jig. My first thought was a sort of router trammel with a semi-arch along the radius that lifts the router as it moves toward the outside; however, this design is limited to a uniformly radiused dish and leaves an area in the center that must be cleaned up.

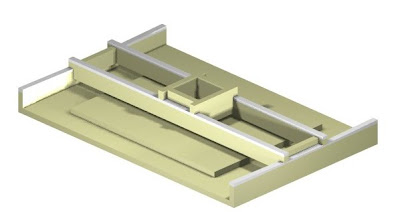

I came across several jigs similar to this:

This jig is closer to what I was thinking but still limited to uniformly radiused dishes. However, I will incorporate this functionality into my jig design.

My initial design was something like this:

It also occurred to me that not only could this design be used to make uniform-radius dishes, but by replacing the separate concave runner on one side of the short axis, I could also create a compound radius. By replacing both concave runners on the long axis with flat ones and both concave runners on the short axis with convex ones, I get a fingerboard radiusing jig. Again, by changing the radius of one runner I can create a compound radius:

One caveat on fingerboard (concave) radiusing: The distance from the outside of the convex arch down to the fingerboard, including the length of the router bit, shortens the effective radius. When you are talking about a 12-inch radius, and inch or two is significant. This means you can also create a single arch radius to use for several radius profiles by adjusting the depth of the router bit. I picked up a 3 Piece Spiral Mortising Router Bit Set from Harbor Freight for $13. It includes a 3-1/4" long 1/2 shank which will give me extra length over standard router bits.

On the other hand, for dishing a radius on the order of 30+ feet, you are increasing the effective radius by the length of the router bit, and I don't think this will make a significant difference to the arch calculation.

If you are trying to do a compound radius fingerboard, then you might need to compensate for any change in height due to the changing radius to keep the fingerboard thickness uniform. This could be accomplished with a thin wedge across the runners.

No comments:

Post a Comment